Selecting the right drill bit for concrete projects can make the difference between a successful installation and a frustrating experience filled with broken tools and damaged materials. Concrete drilling requires specialized equipment designed to handle the unique challenges of masonry work, including the material's density, hardness, and tendency to create dust. Understanding the various drill bit options available and their specific applications helps contractors, DIY enthusiasts, and construction professionals achieve better results while extending tool life and reducing project costs.

The construction industry relies heavily on precision drilling for concrete applications, from simple anchor installations to complex structural modifications. Each drill bit type offers distinct advantages depending on the specific requirements of your project, including hole diameter, drilling depth, concrete composition, and the presence of reinforcing materials. Professional contractors understand that using the wrong drill bit not only compromises work quality but can also lead to equipment damage, increased labor costs, and potential safety hazards.

Modern concrete drilling technology has evolved significantly, offering specialized solutions for various concrete types, from lightweight residential slabs to high-strength commercial structures. The key to successful concrete drilling lies in matching the right drill bit characteristics with your specific application requirements, considering factors such as drilling speed, accuracy, durability, and cost-effectiveness.

Understanding Concrete Drilling Challenges

Material Composition and Hardness

Concrete presents unique drilling challenges due to its composite nature, combining cement, aggregates, and often reinforcing materials like rebar or mesh. The hardness of concrete can vary significantly depending on its age, mix design, and aggregate type, requiring different drill bit approaches. Fresh concrete typically measures between 3,000 to 4,000 PSI in residential applications, while commercial concrete can exceed 6,000 PSI, demanding more robust drilling solutions.

The aggregate composition within concrete creates additional complexity for drill bit selection. Limestone aggregates are generally softer and easier to penetrate, while granite or quartzite aggregates create extremely hard drilling conditions. Understanding your concrete's composition helps determine the appropriate drill bit hardness, cutting geometry, and drilling technique for optimal results.

Heat Generation and Debris Management

Concrete drilling generates significant heat due to friction between the drill bit and material, potentially causing premature tool wear or failure. Effective heat dissipation becomes crucial for maintaining drill bit performance and preventing concrete cracking around the hole. Professional-grade drill bits incorporate design features specifically engineered to manage heat buildup during extended drilling operations.

Debris removal presents another critical challenge in concrete drilling applications. Concrete dust and chips must be efficiently evacuated from the hole to prevent binding, overheating, and poor hole quality. The drill bit design, including flute geometry and surface treatments, directly impacts debris evacuation efficiency and overall drilling performance.

Masonry Drill Bit Types and Applications

Carbide-Tipped Drill Bits

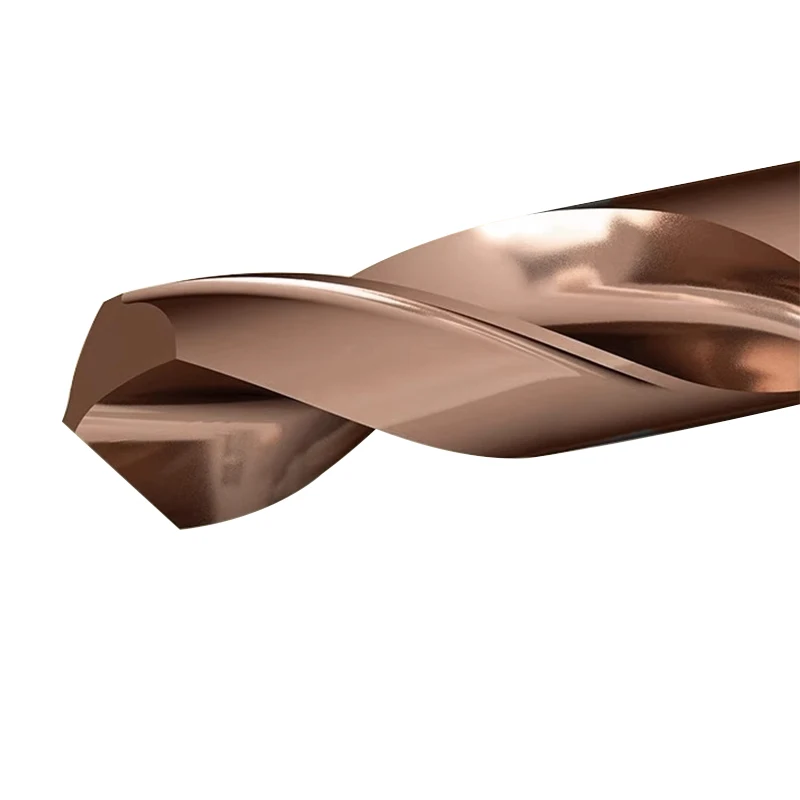

Carbide-tipped drill bits represent the most common choice for concrete drilling applications, offering excellent durability and cutting performance across various concrete types. These drill bits feature tungsten carbide inserts brazed to steel shanks, providing the hardness needed to penetrate concrete while maintaining sufficient toughness to resist breakage. The carbide tip geometry can be optimized for different applications, from general-purpose drilling to specialized tasks requiring precise hole dimensions.

The versatility of carbide-tipped drill bits makes them suitable for both rotary and hammer drilling applications. When used with hammer drills, these bits excel in medium to hard concrete, delivering consistent performance and reasonable tool life. The carbide material maintains its cutting edge longer than traditional steel bits, reducing the frequency of drill bit replacement and improving overall project efficiency.

Diamond-Core Drill Bits

Diamond-core drill bits provide superior performance for demanding concrete drilling applications, particularly when working with reinforced concrete or extremely hard aggregates. These specialized tools feature synthetic diamond segments arranged around a steel core, offering exceptional cutting ability and extended tool life. Diamond drill bits excel in applications requiring precise, clean holes with minimal concrete damage or cracking.

The hollow core design of diamond drill bits enables efficient debris removal and reduces drilling friction, making them ideal for large-diameter holes or thick concrete sections. While diamond-core bits represent a higher initial investment, their extended lifespan and superior performance often provide better value for professional applications or frequent concrete drilling tasks.

High-Speed Steel Solutions for Concrete

Advanced HSS Formulations

High-speed steel drill bits have evolved significantly to address concrete drilling requirements, incorporating advanced metallurgy and surface treatments to enhance performance. Modern HSS formulations include cobalt additions and specialized heat treatments that improve hardness and wear resistance when drilling abrasive materials like concrete. These drill bit options provide excellent value for occasional concrete drilling tasks.

The taper shank design commonly found in HSS drill bits for concrete applications provides superior holding power in drill chucks, reducing slippage during heavy-duty drilling operations. This design feature becomes particularly important when drilling harder concrete types that generate higher torque loads on the drill bit and drive system.

Surface Coatings and Treatments

Advanced surface coatings significantly enhance HSS drill bit performance in concrete applications. Titanium nitride, titanium aluminum nitride, and other specialized coatings reduce friction, improve wear resistance, and help manage heat buildup during drilling. These coatings extend drill bit life and maintain cutting performance longer than uncoated alternatives.

Steam tempering and other heat treatment processes further optimize HSS drill bit performance for concrete drilling. These treatments create a harder surface layer while maintaining a tough core, providing the ideal combination of cutting ability and impact resistance required for concrete applications.

Hammer Drill Bit Technology

SDS and SDS-Plus Systems

SDS (Slotted Drive System) drill bits represent a significant advancement in concrete drilling technology, providing superior power transmission and drilling efficiency compared to traditional round shank designs. The SDS system allows the drill bit to float axially within the chuck while maintaining rotational drive, enabling the hammer mechanism to deliver maximum impact energy to the concrete surface.

SDS-Plus drill bits offer the most common interface for residential and light commercial concrete drilling applications. These bits typically range from 5mm to 20mm in diameter and can effectively drill holes up to several inches deep in standard concrete. The standardized interface ensures compatibility across different hammer drill manufacturers while providing reliable performance and easy bit changes.

Flute Design and Debris Evacuation

The flute geometry of hammer drill bits plays a crucial role in concrete drilling performance, affecting debris removal, drilling speed, and hole quality. Deep flutes with aggressive geometry provide excellent debris evacuation but may reduce drill bit strength, while shallow flutes offer greater durability but slower drilling speeds. Modern drill bit designs balance these competing requirements through optimized flute angles and surface treatments.

Spiral flute designs help transport concrete debris out of the hole more effectively than straight flutes, reducing the risk of bit binding and improving drilling efficiency. The helix angle and flute depth must be carefully optimized for concrete applications to ensure reliable debris removal without compromising drill bit structural integrity.

Specialized Concrete Drilling Applications

Reinforced Concrete Considerations

Drilling reinforced concrete presents unique challenges that require specialized drill bit selection and techniques. When a drill bit encounters rebar or mesh reinforcement, the cutting dynamics change dramatically, requiring bits designed to handle both concrete and steel cutting. Combination drill bits featuring both carbide tips and steel cutting edges provide the versatility needed for reinforced concrete applications.

The location and density of reinforcement within concrete structures significantly impact drill bit selection and drilling approach. Heavy reinforcement may require diamond-core bits or specialized carbide-tipped bits designed specifically for reinforced concrete applications. Understanding the reinforcement pattern helps optimize drilling strategy and tool selection.

Large Diameter and Deep Hole Drilling

Large diameter concrete drilling applications require specialized equipment and techniques beyond standard drill bit capabilities. Core drilling systems with diamond-segmented bits provide the most effective solution for holes exceeding 25mm in diameter, offering superior cutting performance and debris management for thick concrete sections.

Deep hole drilling in concrete demands careful attention to drill bit design, cooling, and debris evacuation. Extended length drill bits must maintain sufficient rigidity to prevent wandering while providing adequate flute capacity for debris removal. Professional applications often utilize specialized cooling systems and drilling techniques to maintain performance during extended drilling operations.

Selection Criteria and Best Practices

Matching Drill Bit to Application

Selecting the optimal drill bit for concrete applications requires careful consideration of multiple factors including hole diameter, drilling depth, concrete type, and accuracy requirements. General-purpose carbide-tipped bits provide excellent versatility for most concrete drilling tasks, while specialized diamond or premium carbide bits justify their higher cost in demanding applications or high-volume work.

Project requirements should drive drill bit selection rather than simply choosing the lowest-cost option. Factors such as hole tolerance, surface finish, drilling speed requirements, and tool life expectations all influence the most appropriate drill bit choice. Professional contractors often maintain inventory of different drill bit types to optimize performance across various applications.

Maintenance and Tool Life Optimization

Proper drill bit maintenance significantly extends tool life and maintains drilling performance throughout the bit's service life. Regular inspection for wear, damage, or coating deterioration helps identify when drill bit replacement or reconditioning becomes necessary. Keeping drill bits clean and properly stored prevents premature wear and maintains cutting edge geometry.

Drilling technique and equipment setup directly impact drill bit performance and longevity. Using appropriate drilling speeds, feed rates, and cooling methods helps optimize tool life while maintaining hole quality. Professional-grade hammer drills and drilling systems provide better control and power delivery, maximizing drill bit performance potential.

FAQ

What makes carbide-tipped drill bits better for concrete than regular steel bits

Carbide-tipped drill bits outperform regular steel bits in concrete applications due to the superior hardness and wear resistance of tungsten carbide material. While steel bits quickly dull when drilling abrasive concrete, carbide tips maintain their cutting edge significantly longer, providing consistent drilling performance and reducing the need for frequent bit replacement. The carbide material can withstand the heat and friction generated during concrete drilling without losing its hardness.

Can I use the same drill bit for both concrete and rebar

Standard concrete drill bits are not designed to cut through rebar effectively and may be damaged when encountering steel reinforcement. For reinforced concrete applications, specialized combination bits with both carbide tips for concrete and steel-cutting capabilities are recommended. Alternatively, you can use a carbide-tipped masonry bit for the concrete and switch to a metal-cutting bit when encountering rebar, though this approach requires more time and skill.

How do I know when my concrete drill bit needs replacement

Signs that indicate a concrete drill bit needs replacement include significantly slower drilling speeds, increased effort required to advance the hole, rough or oversized holes, excessive heat generation, and visible wear or chipping of the cutting tip. When a drill bit begins producing more dust than chips or requires excessive pressure to cut, replacement is typically necessary to maintain productivity and prevent potential safety issues.

What drilling speed should I use for concrete applications

Optimal drilling speeds for concrete applications depend on the drill bit diameter, concrete hardness, and drill bit type. Generally, smaller diameter bits can operate at higher speeds while larger bits require slower speeds to prevent overheating. Most carbide-tipped concrete bits perform best at moderate speeds with steady pressure rather than high speed with light pressure. Hammer drill settings should be adjusted based on concrete density and aggregate type for optimal performance.