Selecting the appropriate cutting tools for machining operations is a critical decision that directly impacts productivity, surface finish quality, and overall manufacturing costs. Among the most versatile and widely used cutting tools in modern manufacturing, endmills stand as essential components for countless machining applications across diverse industries. The effectiveness of any machining operation largely depends on matching the right endmill geometry, coating, and material composition to the specific workpiece material being processed. Understanding these relationships enables manufacturers to optimize their machining processes, reduce tool wear, and achieve superior results consistently.

Understanding Endmill Material Compatibility

High-Speed Steel Endmills for General Applications

High-speed steel (HSS) endmills represent the traditional workhorses of the machining industry, offering excellent versatility and cost-effectiveness for numerous applications. These tools excel when machining softer materials such as aluminum, brass, and mild steel, where their toughness and ability to withstand impact loading prove invaluable. HSS endmills maintain sharp cutting edges longer than carbide alternatives when working with materials that tend to build up on cutting surfaces. Their inherent flexibility makes them particularly suitable for interrupted cuts and applications where tool breakage might be a concern.

The thermal properties of HSS allow these endmills to operate effectively at moderate cutting speeds while maintaining dimensional stability throughout extended machining cycles. This characteristic makes them ideal for prototype work, low-volume production runs, and applications where precision is more critical than speed. Additionally, HSS endmills can be easily resharpened multiple times, providing excellent value for operations that prioritize tool longevity over maximum productivity rates.

Carbide Endmills for High-Performance Machining

Carbide endmills have revolutionized modern machining by enabling significantly higher cutting speeds and feed rates while maintaining exceptional wear resistance. These tools excel when processing harder materials such as stainless steel, titanium alloys, and heat-resistant superalloys commonly found in aerospace and medical device manufacturing. The superior hardness and thermal conductivity of carbide allow these endmills to operate at cutting speeds that would quickly destroy HSS alternatives.

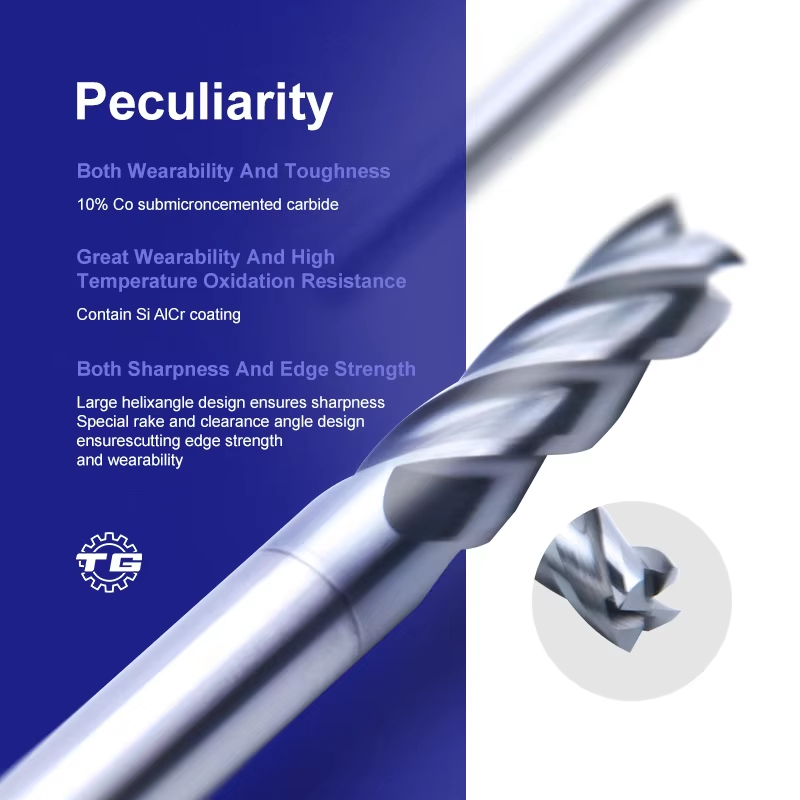

Modern carbide endmills feature advanced substrate compositions and sophisticated coating technologies that further enhance their performance characteristics. Submicron grain carbides provide the optimal balance between hardness and toughness, while specialized coatings like TiAlN, AlCrN, and diamond-like carbon extend tool life and improve surface finish quality. These technological advances have made carbide endmills the preferred choice for high-volume production environments where maximizing metal removal rates directly impacts profitability.

Material-Specific Endmill Selection Strategies

Aluminum and Non-Ferrous Metals

Machining aluminum and other non-ferrous metals requires endmills specifically designed to handle the unique characteristics of these materials. Aluminum's tendency to adhere to cutting edges necessitates endmills with sharp cutting geometry, large chip evacuation flutes, and specialized surface treatments that minimize built-up edge formation. Uncoated carbide or HSS endmills often perform exceptionally well in aluminum applications, as many coatings can actually promote aluminum adhesion rather than prevent it.

The selection of flute count becomes particularly important when machining aluminum, as fewer flutes (typically 2-3) provide larger chip evacuation spaces essential for preventing chip packing and subsequent tool failure. Helix angles between 30-45 degrees help reduce cutting forces while promoting smooth chip flow, contributing to superior surface finishes and extended tool life. Additionally, endmills with polished flute surfaces significantly reduce the likelihood of aluminum pickup, maintaining consistent cutting performance throughout the machining cycle.

Steel and Iron Alloys

Steel machining applications demand robust endmills capable of withstanding the higher cutting forces and temperatures associated with ferrous materials. The diverse range of steel grades, from low-carbon mild steels to hardened tool steels exceeding 60 HRC, requires careful consideration of endmill geometry and coating selection. For general steel applications, endmills with moderate helix angles and 4-6 flutes provide the ideal balance between material removal rates and surface finish quality.

Hardened steels present unique challenges that require specialized endmill designs featuring reinforced cutting edges and advanced coating systems. These applications benefit from endmills with variable helix geometry to reduce chatter, while positive rake angles help minimize cutting forces that could lead to premature tool failure. The selection of appropriate cutting parameters becomes critical, as excessive speeds can cause rapid tool wear, while insufficient feed rates may result in work hardening of the steel surface.

Advanced Endmill Geometries and Features

Flute Count and Chip Evacuation

The number of flutes on an endmill fundamentally affects its performance characteristics and suitability for different materials and applications. Two-flute endmills excel in applications requiring aggressive material removal rates and superior chip evacuation, making them ideal for slotting operations and machining softer materials prone to chip packing. The large flute spaces accommodate substantial chip loads while providing excellent coolant access to the cutting zone.

Four-flute endmills represent the most versatile option for general machining applications, offering balanced performance between material removal rates and surface finish quality. This configuration works exceptionally well for profiling operations and finishing passes where surface quality takes priority over maximum productivity. Six-flute and higher configurations provide superior surface finishes and are particularly effective for finishing operations on harder materials where smaller chip loads are acceptable.

Helix Angle Considerations

Helix angle selection significantly impacts cutting performance, surface finish, and tool life across different material types. Low helix angles (10-20 degrees) generate higher axial cutting forces but provide excellent edge strength for interrupted cuts and rough machining operations. These geometries work particularly well when machining cast iron and other brittle materials where edge chipping might be a concern.

High helix angles (35-45 degrees) reduce cutting forces and promote smoother cutting action, making them ideal for finishing operations and thin-walled part machining where workpiece deflection must be minimized. Variable helix endmills incorporate multiple helix angles to disrupt harmonic vibrations, significantly reducing chatter in challenging applications such as deep cavity machining or unstable workholding situations.

Coating Technologies and Surface Treatments

Physical Vapor Deposition Coatings

Physical vapor deposition (PVD) coatings have transformed endmill performance by providing enhanced wear resistance, reduced friction, and improved thermal stability. Titanium nitride (TiN) coatings offer excellent general-purpose performance and easy wear detection through their distinctive gold color. Titanium aluminum nitride (TiAlN) coatings provide superior high-temperature performance, making them ideal for high-speed machining applications where thermal stability is critical.

Advanced multi-layer coatings combine different materials to optimize specific performance characteristics for targeted applications. Aluminum chromium nitride (AlCrN) coatings excel in high-temperature applications while providing excellent oxidation resistance. These sophisticated coating systems enable endmills to operate at previously impossible cutting parameters while maintaining consistent performance throughout extended production runs.

Specialized Surface Treatments

Beyond traditional coatings, specialized surface treatments further enhance endmill performance for specific applications. Diamond-like carbon (DLC) coatings provide exceptional lubricity and wear resistance when machining non-ferrous materials, while maintaining the sharp cutting edges essential for superior surface finishes. These coatings are particularly effective in dry machining applications where traditional coolants cannot be used.

Cryogenic treatment processes improve the dimensional stability and wear resistance of endmill substrates by relieving internal stresses and promoting carbide precipitation in steel-based tools. This treatment significantly extends tool life in demanding applications while improving dimensional consistency throughout the tool's service life. The combination of advanced substrate treatments and sophisticated coating systems represents the current state-of-the-art in cutting tool technology.

Application-Specific Endmill Selection

Aerospace Material Challenges

Aerospace manufacturing presents unique challenges that demand specialized endmill designs and material compositions. Titanium alloys, commonly used in aerospace applications for their exceptional strength-to-weight ratios, require endmills with sharp cutting edges and conservative cutting parameters to prevent work hardening and galling. The low thermal conductivity of titanium necessitates endmills with excellent heat dissipation characteristics and coatings that maintain stability at elevated temperatures.

Inconel and other nickel-based superalloys demand endmills with extreme wear resistance and the ability to maintain cutting edge integrity under severe thermal cycling conditions. These materials work-harden rapidly, requiring constant engagement and positive cutting geometry to prevent built-up edge formation. Specialized endmill designs featuring reinforced cutting edges and advanced cooling strategies enable successful machining of these challenging materials.

Medical Device Manufacturing

Medical device manufacturing requires endmills capable of achieving exceptional surface finishes and dimensional accuracy while working with biocompatible materials such as stainless steel, titanium, and cobalt-chromium alloys. The stringent cleanliness requirements in medical applications often prohibit the use of cutting fluids, necessitating endmills with coatings optimized for dry machining conditions.

The miniaturization trends in medical devices have driven demand for micro-endmills capable of machining intricate features with tolerances measured in micrometers. These specialized tools require exceptional runout accuracy and substrate uniformity to maintain cutting performance at the microscopic level. Advanced manufacturing techniques and quality control processes ensure these precision tools meet the exacting requirements of medical device production.

FAQ

What endmill material is best for machining stainless steel?

Carbide endmills with TiAlN or AlCrN coatings typically provide the best performance for stainless steel machining. These tools offer the hardness needed to resist the work-hardening characteristics of stainless steel while maintaining sharp cutting edges. The coatings provide thermal stability and lubricity essential for managing the heat generated during stainless steel cutting operations. Four-flute configurations with moderate helix angles generally deliver optimal results.

How do I choose the right flute count for my application?

Flute count selection depends on your material type and machining objective. Use 2-3 flutes for aluminum and softer materials where chip evacuation is critical. Choose 4 flutes for general steel machining and balanced performance. Select 6 or more flutes for finishing operations on harder materials where surface finish quality is the primary concern. Consider your machine's rigidity and spindle speed capabilities when making this decision.

Can HSS endmills be used for all materials?

While HSS endmills are versatile, they are not optimal for all materials. They excel with softer materials like aluminum, brass, and mild steel, particularly in applications with interrupted cuts or where tool toughness is important. However, HSS endmills struggle with harder materials like stainless steel, titanium, or heat-treated steels where carbide alternatives significantly outperform them in terms of speed, feed rates, and tool life.

What coating should I choose for high-temperature machining?

For high-temperature machining applications, TiAlN (Titanium Aluminum Nitride) and AlCrN (Aluminum Chromium Nitride) coatings provide excellent thermal stability and oxidation resistance. These coatings maintain their properties at temperatures exceeding 800°C, making them ideal for high-speed machining operations. Diamond-like carbon coatings work well for non-ferrous materials, while uncoated carbide sometimes performs better than coated alternatives in specific aluminum applications.